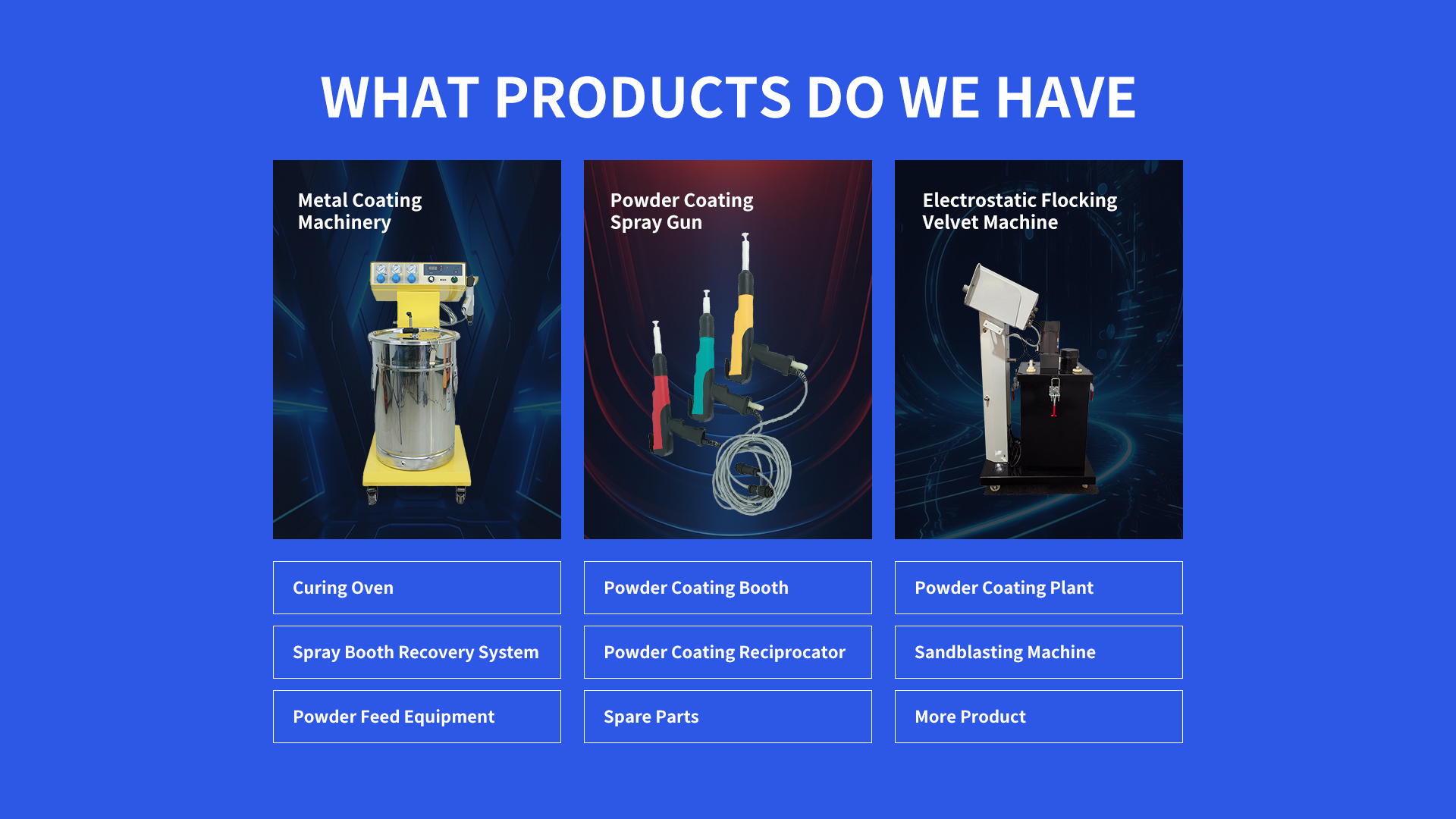

In the powder coating field, the

Manual Powder Coating Machine is a revolutionary device for small - scale operations. It has brought about a significant transformation in the way small - scale coating tasks are carried out.

A

Manual Powder Coating Machine consists of a powder - feeding unit. Typically, this unit is a hopper equipped with a flow - control mechanism, such as a valve, which enables precise regulation of the powder supply. The spray gun, being the core component of the machine, may incorporate an electrostatic charging element. This element plays a crucial role in enhancing the powder's adhesion to the workpiece, ensuring a more uniform and durable coating. Additionally, some models are equipped with an air supply system. This system provides the necessary force to assist in the powder spraying process, facilitating a smooth and efficient application. Complemented by a straightforward control panel, users can easily make basic settings to customize the coating process according to their specific requirements.

DIY enthusiasts find the

Manual Powder Coating Machine to be an invaluable tool for coating small metal items. Whether it's adding a unique finish to home - made decorations or giving a new look to small metal crafts, this machine allows for creative and personalized projects. Small - scale manufacturers also heavily rely on it. In the jewelry - making industry, it enables the production of high - quality, visually appealing pieces with consistent coatings. For small - scale furniture hardware production, it ensures that the hardware components are not only functional but also aesthetically pleasing. In the automotive aftermarket, the machine is indispensable for refinishing small car parts. It helps restore the appearance and protect the parts from corrosion, extending their lifespan.

For beginners who are just starting to explore the world of powder coating, basic models are available at a relatively affordable price range of around $100 - $300. These models are designed to provide the essential functions and are a great entry - point for those new to the craft. Mid - range machines, which are equipped with better - quality components, offer improved performance and more precise control. They are priced between $300 - $800. High - end models, on the other hand, come with advanced features such as more sophisticated electrostatic charging systems, precise powder - flow control, and enhanced durability. These models are priced over $800 and are ideal for professional users or those with high - volume and high - precision coating requirements.

Prior to using the

Manual Powder Coating Machine, it is essential to properly assemble all the components. This ensures that the machine functions optimally and safely. Next, prime the powder - feeding unit to ensure a smooth start to the powder - delivery process. Adjust the settings according to the type of workpiece, the desired coating thickness, and the powder characteristics. During the spraying process, hold the gun perpendicular to the workpiece. Maintaining a distance of 15 - 20 cm is crucial as it helps achieve an even coating distribution. Move the gun steadily and at a consistent speed to avoid any unevenness in the coating. After use, it is imperative to clean the gun and the powder - feeding unit thoroughly. This not only helps maintain the performance of the machine but also prevents cross - contamination if different powder types are used in the future.

When choosing a

Manual Powder Coating Machine, several factors need to be considered. First and foremost, assess your skill level. If you are a beginner, starting with a basic model is a wise choice. It allows you to gain experience and familiarity with the powder - coating process without a significant investment. As you become more proficient, you can upgrade to a mid - range or high - end model. Consider the types of projects you will be working on. If you are primarily involved in small, simple projects, a basic or mid - range model may suffice. However, if you are dealing with complex shapes, high - precision requirements, or a large volume of work, a high - end model may be more suitable. Your budget also plays a crucial role in the decision - making process. Set a realistic budget and look for a machine that offers the best value for your money within that range.

Safety should always be a top priority when using a

Manual Powder Coating Machine. Wear a dust mask to prevent the inhalation of powder particles, which can be harmful to your respiratory system. Safety goggles are essential to protect your eyes from any potential powder splashes or flying debris. Gloves provide protection for your hands, preventing skin contact with the powder and any chemicals present in it. Work in a well - ventilated area to ensure that any powder fumes or particles are effectively removed from the working environment. For electrostatic models, ensure proper grounding. This is crucial to prevent the build - up of static electricity, which could lead to electrical hazards or inconsistent coating results.

The

Manual Powder Coating Machine offers several advantages, making it a highly rational choice for small - scale use. Firstly, it is cost - effective. Compared to larger, more industrial - scale powder - coating equipment, the manual machine is much more affordable, allowing small - scale users to enjoy the benefits of powder coating without a large capital investment. Secondly, it offers great flexibility in coating different workpieces. Whether it's a small, intricate jewelry piece or a larger furniture hardware component, the machine can be adjusted to suit various shapes and sizes. Its user - friendly design also makes it accessible to a wide range of users, from DIYers to small - scale manufacturers.

Q: What if the powder doesn't stick?

A: First, check the electrostatic settings to ensure that the charging is optimal. Next, clean the workpiece thoroughly to remove any dirt, oil, or other contaminants that may be preventing the powder from adhering. Finally, adjust the powder - flow rate. A too - high or too - low flow rate can affect the adhesion of the powder.

Q: Can I change powder types?

A: Yes, you can change powder types. However, it is essential to clean the machine thoroughly between changes. This helps prevent cross - contamination and ensures that the new powder provides the desired coating results.

Q: How often should I clean the gun?

A: It is recommended to clean the gun after each use. This helps maintain the performance of the gun, prevents clogging, and ensures consistent powder spraying.

Q: What if the powder - flow is inconsistent?

A: Check for blockages in the powder - feeding unit, the hose, or the gun nozzle. Also, look for signs of powder compaction. If the powder has become compacted, it can disrupt the flow. Loosen the powder and ensure a free - flowing state.

Q: Can I upgrade the electrostatic unit?

A: It may be possible to upgrade the electrostatic unit. However, before doing so, check the compatibility of the new unit with your existing machine. Contact the manufacturer for guidance to ensure a successful upgrade.

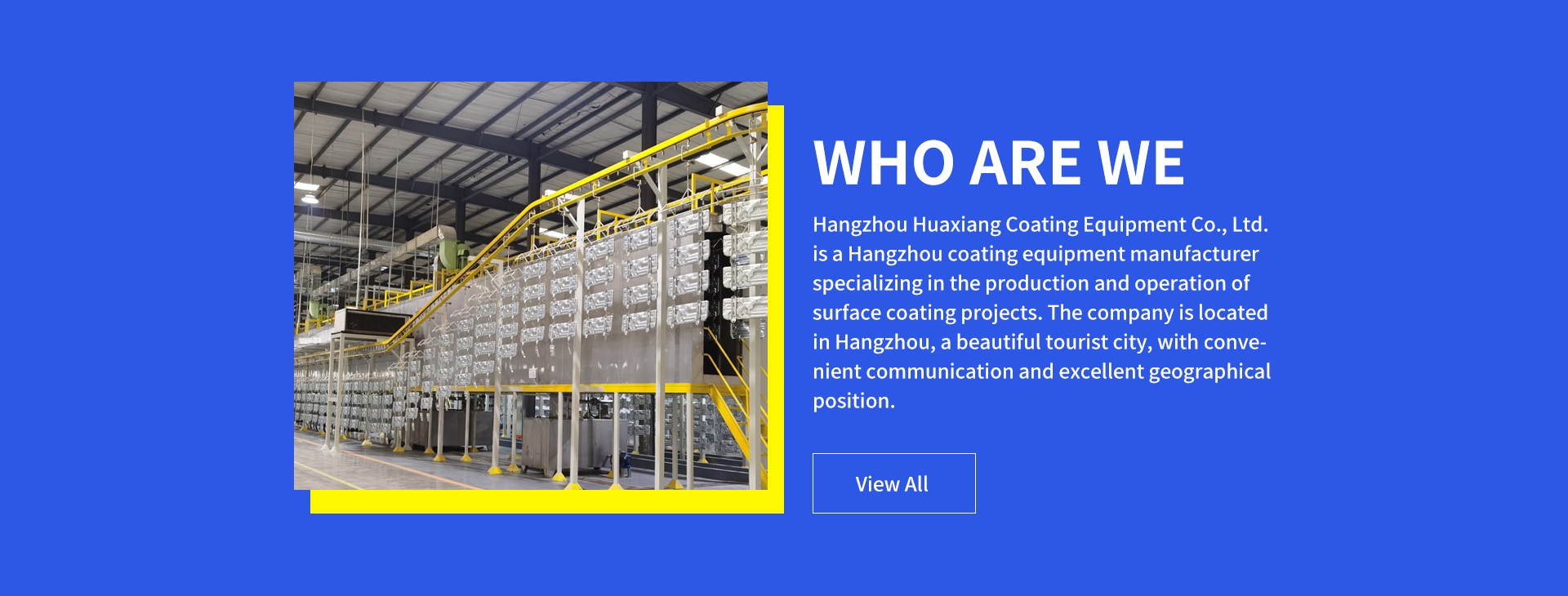

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com